What is X70 Pipe?

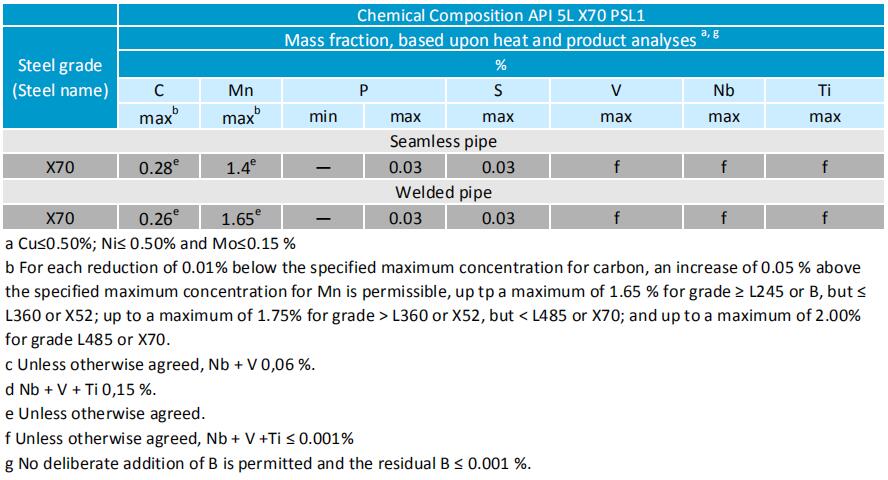

The API X70 steel pipe is comprised of carbon steel and contains alloying elements. Along with carbon, the API 5L X70 material also contains silicon, manganese, phosphorus, sulphur, and niobium. Manganese and silicon percentages are higher in the alloy used to make API 5L X70 tubular pipes, API 5L X70 Seamless Pipe Suppliers. Additional elements like phosphorus, sulphur, and niobium are present in trace levels. The mechanical properties of the X70 Pipe Material are improved by the addition of these compounds to the alloy.

The L485 pipe is another name for the widely used API 5L X70 pipe. From 1″ to 26″ in diameter, it is available. This grade is offered with pipe lengths ranging from 3 metres to 12 metres and wall thicknesses starting at SCH 10, SCH 20, SCH 30, STD, SCH 40, up to SCH 60. API 5L X70 Tubular is the pipe standard, whereas CSA Z245, ASTM A53, A106, or other standards are equivalent grades.

Features of X70 Pipe

The minimum yield strength for API 5L X70 steel pipe is 70,300 psi, or 485 Mpa. The carbon-manganese steels used in the modern X70 steel pipe are all regulated micro-alloyed steels. The major components of micro-alloys are Nb, V, and Ti, and their overall content doesn’t go above 0.15 percent. Because of this, the pipe’s structure is made of acicular ferrite and bainite, and it typically performs well during welding.

Advantages Of API 5L X70 Pipe:

- High power.

- Strong dynamic tearing resistance.

- Impact toughness at high and low temperatures.

- Lower than average ductile-brittle transition temperature.

- The suitability of acid services.

- Long-lasting and affordable

The ultra-low carbon acicular ferrite structure, high density dislocations, and fine precipitation phases interact to provide it exceptional performance.

API 5L X70 Pipe Specifications:

Know more about API 5L X70 Pipe Specifications at Eckhardt Steel.