Introduction Research labs:

Research labs assort and process a wide range of data that becomes central to research and innovation. But poor data management is the pitfall to lab efficiency. Using traditional data management systems is one of the biggest obstructions for research teams in reaching their maximum output potential.

It is 2022, yet many research labs collect data manually with a pen and a notepad. Some laboratories generate so much information that they need a team of personnel to manage data, sort, and organize it.

Limitations of Traditional Data Collection and Management

Putting this data up in the spreadsheets only serves the purpose until the end of the experiment. However, it is not an efficient way to manage data for future uses. This results in low productivity, high R&D costs, and sometimes even loss of important data.

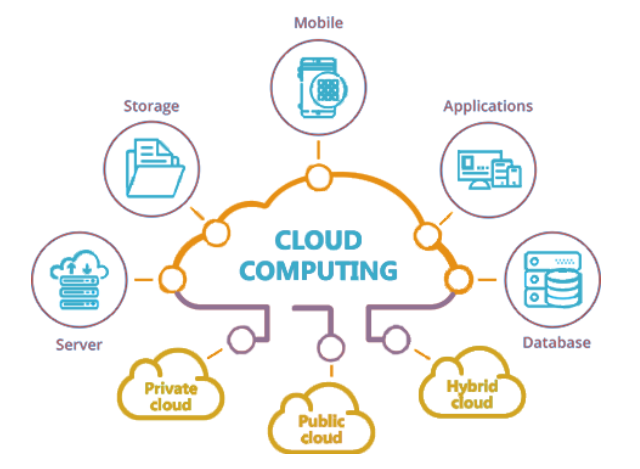

Luckily, there is a solution to this inefficiency- leveraging cloud technology for data management.

Cloud technology allows sharing files and data using a secure off-site server or ‘cloud’ storage. It enables easy access to the team members from anywhere and anytime.

A cloud data management system also steps up your data storage and analysis game, expediating the analytical process of unstructured data files.

Advantages of Using Cloud Technology for Data Storage and Management:

Cloud technology can be a beneficial addition to your research lab’s productivity in many ways:

- It unifies data management features and AI algorithms to provide insights and recommendations.

- Allows team members to work on projects together efficiently with off-premise file storage that provides flexible access to the data.

- Cloud templates eliminate manual data modification for analysis and save tons of time.

- Paired with AI/ML it breaks the traditional long cycles of trial and error-based development and eases Lab automation.

- It saves the cost of running onsite server rooms for data storage to reduce your budget.

- It saves physical space, energy, and additional data management personnel.

- It will be working in the same format of data input, and minimizes the chances of human error in manual lab techniques, further minimizing the company’s R&D budget.

Digitalization in Research Labs

With the moving age of digitalization, research labs must adopt state-of-art data management technology to maximize research output and minimize the development time and cost. Employ cloud technology for data management for your innovation in R&D facilities and harvest the power of ML to optimize your research lifecycle with us.

Polymerize’s cloud technology unifies the data management features by providing insights and recommendations. Our AI engines can generate predictions with great accuracy even from a smaller data set.

We save your company 40% on R&D cost and time, as vouched by our chemical and polymer supply chain clients who have benefited from our Cloud-Based Material Informatics Platform. And we strive for security without compromising privacy. Our clients get sole IP rights for any new and improved formulations.

Conclusion:

Research labs are crucial for innovating and modifying products to remain relevant in the competitive market. However, their efficiency largely depends on research data management, application, and automation.

An efficient cloud-data management system makes these processes easier, and with analytical abilities, it can predict the experiments for desirable outcome requirements.

Together with Machine Learning and Artificial Intelligence, cloud computing can enable research labs to optimize productivity and save valuable money on operational costs.

Partner with us and get seamless data management solutions today. If you want to accelerate your laboratory process by integrating cloud technology, request our Product Demo here!

What is Material Informatics?

Materials informatics deals with the intersection between materials science and artificial intelligence particularly focusing on developing new materials.

Materials are like human beings possessing very distinct characteristics/ features generated from their inherent structural attributes and fabrication conditions.

Therefore, the performance and functional attributes of the materials such as mechanical performances, chemical behavior, thermal, and thermo-mechanical properties are difficult to forecast and require long-term experimental approaches.

This conventional mode of the experimental approach is costly as well as time-consuming. Moreover, the process requires experience/expertise in performance evaluation/ characterization.

In this regard, material informatics creates a platform to accelerate this process with the help of modern computing facilities such as artificial intelligence and machine learning to understand the nonlinearity between the product composition and performance attributes thereby accelerating product development.

Polymerize Material Informatics

The process requires experience/expertise in performance evaluation/characterization. In this regard, material informatics creates a platform to accelerate this process with help of modern computing facilities such as AI/ML to understand the nonlinearity between product composition and performance attributes thereby accelerating product development.

Polymer is a popular class of material that requires no introduction as it is largely involved in our daily usage. Therefore, bringing polymer science with material informatics together as polymer informatics will open up a wider perspective for developing new materials with optimal composition and performance attributes offering a versatile range of functional applications.

Polymerize with domain-specific expertise in polymer informatics is determined to provide solutions for accelerated innovation with an experienced team of young professionals led by Dr. Abhijit Salvekar and Mr. Kunal Sandeep.

How much data is needed for materials informatics?

The accuracy and acceptability of material informatics are governed by the relevant data availability and reliability. Similarly, the performance of the AI/ ML engine runs with the quality and quantity of available data set which is system-specific.

However, the system nonlinearity and desired output variables demand adequate data filtering and selection of control factors (directly influencing the outcomes).

In terms of determining the accuracy of the model, the utmost need is to understand the factors/ variables directly influencing the outcome therefore requires supreme expertise and understanding. With an experienced team of polymer scientists and engineers.

Polymerize has successfully demonstrated the caliber to showcase its proficiency in data management and data filtering for developing the material informatics platform successfully.

Driven by the knowledge and experience of our employees, Polymerize has developed an opportunity to manage the available experimental data set from the customer’s end and reuse it for future goals.

This will not only reduce the tedious experimental exercise but also provide a thorough understanding of the domain. Also, aids in emphasizing the factors, which are majorly influencing the outcomes.

ROI of materials informatics

Return of investment (ROI), is the ratio between the investment benefit and the investment cost. Creating materials for the functional applications is time-consuming and required synthesizing chemicals and engaging an experienced workforce which will take several weeks/ months.

On the flip side, artificial intelligence requires only a few minutes to guide the researchers toward the most likely experiments to bring success. Therefore, the trial and error are replaced with a domain-specific data-driven path.

The material informatics platform

The material informatics platform from Polymerize guides the product formulation process based on the earlier data set and suggests the most likely condition for reducing the uncertainty.

Moreover, the suggested formulations are tested and the results are added to the platform for improving the desired accuracy of the model. Therefore, achieving high-performance adequate formulations quicker than the trial and error method. These are the advantages of Polymerize material informatics platform brings regarding the product development process.

- Reducing the number of experimental trials reduces initial investment costs.

- Extravagant reduction of time leads to fresh profits.

- Making processes robust, efficient and satisfying multiple objectives helps in the reduction of production costs.

- Optimization increases product value and brings out unseen discoveries.

- Codifying knowledge from experiments serves as a digital asset for future research.